ABOUT US

MISION

VISION

VALUES

Polykon Envases is a Mexican company belonging to the AGA group. Its main focus is the manufacture and sale of carbonated beverages, which in 1994 opened this branch to cover its needs in the supply of preforms.

Currently we have an installed capacity for the manufacture of preforms of more than 1400 million annually, satisfying the national and international market positioning us as leaders in the industry.

To achieve our challenges and maintain an integration with society, Polykon Envases has stimulated the ideology of all staff with the support of our ideals.

To provide quality plastic products that exceed the expectations of our customers through innovation, continuous improvement of processes and staff development. Guaranteeing the profitability and sustained growth of Polykon in harmony with the environment.

To be a world class company, achieving a diversification of products and clients, assuming the leadership in the plastic industry, accessing international markets.

Commitment: Positive attitude and willingness to do the job well, at first and always.

Continuous improvement: optimize day by day all our activities.

Honesty: compliance with all guidelines established by our organization.

Respect: the good treatment between all the members of the organization.

Teamwork: collaborate all towards the same goal or goal.

Innovation: Apply new ideas, concepts, products, services and practices that generate productivity and benefit to our customers.

1993

Embotelladora AGA analyzing the market change in the use of glass bottle for plastic, assigned to the branch Policajas develop the project for the manufacture of preforms and taparoscas for packaging of soft drinks and purified water.

1994

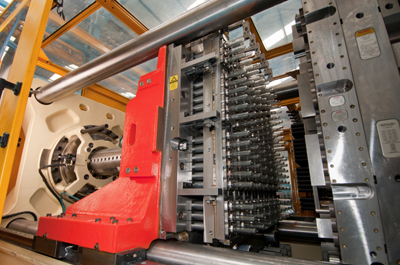

The preform manufacturing area was created within the Policajas branch. Starting with an LX 300 machine with an annual capacity of 59.4 Milions. providing preforms R.28 PCO of 48 y 51 grams.

1995

The second machine was installed, a SX 600, increasing installed annual capacity to 186 millions, adding the R.28 PCO of 25 and 27 grams formats.

1996

Two resin storage silos with a capacity of 150 tons each are installed.

2000

The sale is opened to external customers, serving the western and Pacific area of the country.

2004

A third machine is installed, a Hypet 300, increasing the anual capacity to 375 millones, extending the production line to R.28 PCO de 18, 20, 30, 35 y 40 grams preforms.

ISO 9001:2000 certificaction proyect was started.

2005

The fourth Hypet 300 machine is installed, increasing the annual capacity to 484 million, also offering preforms of 19 and 23 grams.

A third silo is installed, this one with capacity of 300 tons, increasing the storage capacity to 600 tons of resin.

ISO 9000; 2000 certification is achieved.

2006

The fifth Hypet 300 machine is installed, increasing the annual capacity 644 million.

Sucursal Policajas transforms its image, becoming Polykon Envases Branch, initiating a new facet in marketing and promotion for clients.

2007

The sixth and seventh Hypet machines are installed, one 300 and one 120 tons, increasing the annual capacity to 884 million preforms, with the new formats R.24 of 13, 16, 19 and 23 grams.

All machines have conveyor belts and counters.

2008

The eighth machine is installed a Hypet 400 High Performance, increasing annual capacity to 1,200 million preforms.

We begin the sale of Preform PCO Corvaglia (Short Neck) in response to the request of our customers in the search for designs that allow savings in the price of the preform.

Our range of formats is again extended, offering R.48 preforms in 80 and 90 grams.

Recertification is achieved in ISO 9000; 2000.

2009

We installed a new automated storage system that provides an optimal preservation of the preform and allows us to have a total availability of our products to respond quickly to the needs of our customers.

It complements the line of preforms of Thread 48mm with the new format of 75 grams.

2010

With the constant growth of the company, the Industrial ship is extended and the ninth machine is installed a Hypet 500 High Performance, achieving a capacity of more than 1400 million annual preforms.

We work on the innovation of preforms to become competitive advantages for our customers, thus emerges our short neck with ecobase and expanding range of formats.

The Lean Six Sigma project begins, which through the use of all tools of lean manufacturing and six sigma will allow us to be more agile, to have more controlled operations, to reduce waste, variations and to work with lower costs always thinking about a product with opportunity and with the best quality.

2011

We extend our range of formats with short neck, offering thread 28 short neck now in 28 and 34 grams.

We have implemented the operation and application of Lean Manufacturing & Six Sigma tools, optimizing our operations and achieving shorter reaction times, improving customer service, quality and cost.

2012

It is possible to develop and introduce to the market the preform of Thread 26 mm. CSN in its different weight: 11.52, 17, 19 and 20.5 grams.

2013

Extending the variety of products, the Sport Cap is the most innovative on the market, working for threads 1181, 1873 and Corvaglia, as well as being a cap injected in one piece.

Also begins the sale of Agrochemical bottle in its versions MISIL and MISIL PRO being the latter an innovative design, both with resistance of 3 atmospheres in implosion as explosion.

2014

With the constant growth in products for our customers, the Preform 660/700 for carafe is introduced to the market, keeping our commitment to quality and trust towards our customers.

1993

1994

1995

1996

2000

2004

2005

2006

2007

2008

2009

2010

2011

2012

2013

2014

Our Journey

Antiguo Camino a Tesistán 680 | Zapopan, Jalisco, México | Tel. (011 52 33) 3633-7679, 3633-7690 | email: info@polykon.com.mx

All rights reserved © 2017. Polykon Envases.